Your software is better

People like InvenTex

“Your software is better – very clear and well ordered. With that presented on the screen, what is just necessary”

“Savings on fabrics what we have got here at once after start-up InvenTex Intelligent Master Marker module meant return of investment for InvenTex…. within 1 week only!

Now we continuously get savings earning more money!”

“InvenTex is easy for operation and easy to understand. For me, pattern designer, this is a very good tool. I work quite effectively, do not learning on computer systems.”

“I have spent 5 hard working hours trying to make the best optimized marker, to prove InvenTex Intelligent Master Marker cannot beat me. When I’ve started IMM module, within 3 minutes it has got a result better of mine by 2%! This was really unbelievable how fast and efficiently IMM makes markers that looks close to perfection.”

“Maybe another system I worked with for last 4 years can do same things I make now on InvenTex. But I admit, I didn’t know how to make it there. InvenTex is for me much more intuitive.”

“We cooperate with other companies that use other CAD systems. I was afraid that data interchange between us will be difficult and troublesome. At the beginning there was need to learn a little more on data interchange general and

specific rules. Now this is behind us, and it’s Ok.”

“I know that using InvenTex I can make all the model within 15-30 minutes! And this with verification of distances

for corresponding lines to be sewn together. Interactive Measurement Table is a perfect tool I never seen before at any other CAD system I’ve used before. When I see “zero” values for sewing control measurements, I’m sure it fits correct.”

I worked on the old CAD system and we wanted to replace it for something new and better. But the old digitizer and the old plotter were still good. Finally we have choosen InvenTex and we do not regret. I have now many new capabilities, not accessible before. All very simple and very intuitive. And the old digitizer and the old plotter are successfully connected and are still running.”

“We have thought to buy and implement CAD system into our manual pre-production process by last 5 years or more. I was thinking, I was sure it costs too much. We have bought InvenTex, and now I see how wrong I was! Though now I’m really happy to use it, anyway very often a question returns to my mind: why I didn’t take it earlier? Now it’s clear for me, how much money I’ve lost by this “waiting time”. We ’ve lost money, some clients and some business opportunities.

Now we rebuild our good statement step by step.”

Main Benefits for the Users

• End of paper templates! Easy and well ordered management over models, patterns and markers in the computer

• Availability of easy to use all the tools for patterns efficient design

• Always correct, mistake-free patterns thanks to digital processing and control by computer system

• Digital patterns processing in garment gives possibility to operate with almost unlimited range of sizes

• Minimization of fabrics consumption with Intelligent Master Marker module what makes top efficient markers within minutes

• High, stable products quality thanks to supply always the correct shape cut elements to the production

• Shortest training and start-up time. Unmatched user-friendly, modern and well ordered user interface

• Systemandinterfaceeasilycustomized, accordingtoindividual user necessities or preferences

• Multi-operator system – all operators connect and operate with one SQL database, always serving the actual data

• Data interchange with all professional CAD systems, cooperation with all professional digitizers, plotters, cutters

• Return of investment in the shortest time – continuous, extra profits collected during long-term use

• InvenTex CAD – innovative computer system for pre-production processing on garment, upholstery and every other textile production.

• InvenTex CAD – complex 2D patterns processing: digitalization of paper patterns, pattern design and modeling, patterns grading (garment), markers making.

• InvenTex CAD – system that helps to be in the first line of competitiveness and efficiency, to survive on difficult market.

• InvenTex CAD – the highest standard of data protection, ensuring that your information are always secure.

• InvenTex CAD – pleasant and efficient system, that supports high creativity, production flexibility, high productivity and competitiveness.

Your software is better – very clear and well ordered. With that presented on the screen, what is just necessary”

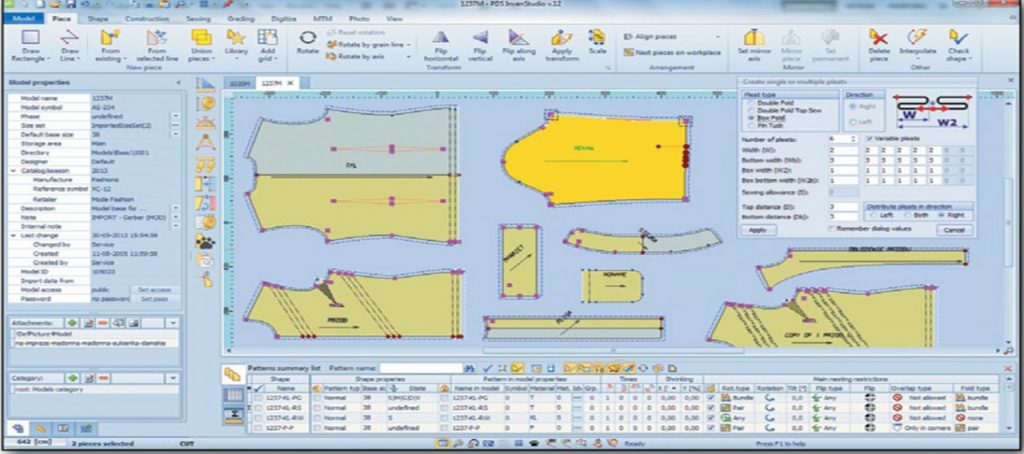

PDS

Pattern Design System

InvenTex PDS – modern system, enabling the most ergonomic, intuitive and comfort operation with the patterns on the com- puter screen. Perfectly realizes all needs concerned to patterns design at pre-pro- duction process. InvenTex PDS – pattern design is made in computer, without use of ineffective and prone to errors manual working methods. Advanced functions

makes every working day more comfortable and limits-fre for high skilled operator mak- ing complex job.

Program Main Functions / Benefis for Users

• Ability to input patterns with traditional digitizers, by photo-digitizing or by import from other CAD systems

• Create new and change existing patterns quickly and intuitively directly on your com- puter

• All necessary tools for patterns modeling and design: darts, pleats, ruffles, notches, various forms of angles, symmetry, adding internal lines and marks, etc. – with ability for change at any moment

• Work with many open models in same time for easier pattern recognizing and easier el- ements transfer between different models

• Recordable user-defined, unlimited pat- terns arrangements on the screen work area

• Ability to work at the contour line (pattern line) or seam line (form line), depending on the actual processing need, with easy switch between

• Advanced function of interactive fitting pat- tern to pattern (walk function) simulates stitching of corresponding pattern parts

• Professional, modern and precise zoom methods

• Unmatched possibilities of product catalog- ing, the most effective product searching and exploring methods, advanced data fil- tering

• We can attach to every product/model un- limited files with additional information at any format

• Curve lines are Bezier curves – the most suit- able, convenient and professional way to work with curve contour

• All functions are interactive with a preview of their result prior to actions confirming

• Dynamic measurement of the line lengths, with the possibility to put selected dimen- sions to the interactive comparison table

• The largest work area on the screen, most information on one screen, work with full resolution Full-HD or higher (1920×1200,

2.3 million pixels)

• Active prompts on the subsequent steps to follow for more advanced functions, make work easier and faster

• and many others…

PGS

Interactive, advanced grading of garment patterns

InvenTex PGS provides a perfect grading module, specialized for garment applications. It ensures incomparable time savings and the best grading functions. Grading facilitates size variations. If required, we can define two, three, four or even more parameters (values) describing the size (e.g. circumference, height and figure style). InvenTex is an unique system, that can process the highest quality garment production. Within a few minutes we can grade a model at hundred sizes. Extension of any sizing table is unlimited at any time. This is not reachable with manual grading operation. Time spent for completion grading process of the 100-sizes model usually does not exceed 10-20 minutes. We evaluate this can be 100 times less in comparison to make it manually. If job is made manually, to modify it, this is so time-consuming that mostly not possible to do!

Main Benefits for the Users

• Lots of user-friendly tools for professional interactive grading

• Efficient unlimited sizes grading – within minutes we can grade 50-, 100- or 200-sizes model

• Grading completion for 100-sizes model normally does not exceed 15-30 minutes – this is 10-100 times more efficient than manual making

• InvenTex CAD grading provides significant savings of time and money, increase productivity and quality

• Possible correction of shape and/or grading rules individually in any one size of the complete size set

• Every size convenient display on the screen with different color

• Grading rules can be copied freely between points, lines or the entire patterns

• Many different grading methods available: increments in X and Y coordinates, increments given in tangential and perpendicular lines, increments as distances measured along the line (notches, etc.).

• Possiblerotationof Xand Ycoordinatesbyadefinedanglefrom base X and Y position, to define increments more conveniently in some cases

• and many others…

DIG

Conversion of traditional patterns for the digital ones in the computer

InvenTex CAD uses interactive digitizer table for conversion traditional patterns to a digital format, all visible on the screen while digitizing. We can digitize all types of contours with inner elements, at once assigning to them all necessary attributes and/or information.

Digitization with digitizer board:

• We can digitize and automatically grade all the sizes in the model, simply by digitizing patterns set of two different sizes.

• Digitization process is accompanied by a voice assistant, which facilitates the user time savings, provides the convenience and precision of a workflow.

• Auto-joining feature allows the use of digitizers of any, even small size, regardless of the size of the patterns.

• Digitization of all patterns, regardless of their quality and format.

IPD

InvenTex Photo Digitizer

Innovative solution for a fast patter digitizing using a digital photo camera

For significant speed-up of patterns digitizing, we have developed the advanced InvenTex Photo Digitizing module. Using a standard digital photo camera we can easily and quickly transform any size paper patterns to digital form. System auto- matically calibrates patterns from the photo in pur- pose to remove any optical or spherical aberration fault effects. In a very short time, shapes for all shot patterns are autmatically recognized and saved in computer memory. Advanced algorithm for image processing ensures high precision of digital shapes transformation. The innovation is we can shot the photos by photo camera mounted on a fixed sup- port or shot by hand. We get full mobility. Without need to make a calibration of photo-camera struc- ture each time, when camera position changes in relation to a surface that digitized patterns are set.

Three easy operations, to speed-up a few times patterns digitiz- ing process, getting the highest accuracy at a time:

Three digitizing methods delivered in one software. You can always choose photo-digitizing method best fitting to circumstances.

Integraly built-in into PDS module InvenTex Photo Digitizer assures the best operability. It can be anyway supplied as a separate module capable to be used with any other CAD software.

• High efficiency thanks to direct photo-camera connection with a computer capturing an image at once

• Continuous preview of digitized patterns on computer screen makes possible to set patterns best position on a table surface

• High image quality by using a professional photo-camera

• Ability to use any table covered with non-reflex black fabric

• Solid support keeps camera fixed avoiding calibration repeating

• Patterns easily set on a table lying firmly by their own weight

• Ability to use any photo-camera with min. 6 MPix. dot-matrix

• Full mobility to make photo-digitizing in any place, ex. make pat- terns images at client place, then process them after return back

• Innovative auto-calibration method, processed for each image rec- ognize, guarantees high accuracy for pattern shape transform.

• Saves a surface by installing black table on a wall

• The best price rate in compare to function capabilities

Solution with a scanner and auto-calibration

• Ability to use any cheapest flat scanner of A4 format

• Comfortable method for digitizing small patterns (lingerie)

• Half-pattern scan method for internally symmetrical pattern

• Ability to connect & use a professional, wide-format scanner

MGS

Marker Generation System

Effective markers planning of highly optimized markers for a cutting room

InvenTex MGS marker generation software module, this is a very strong tool of InvenTex CAD system. Using of the module gives at once significant, at least 5% material savings. Intuitively grouped functions for easy operation. Intelligent Master Marker module intelligently and automatically creates the markers with the highest efficiency (lowest material waste) and in the shortest time. The system supports checks, strips and/or pattern fabrics. Fabric consumption when creating the

marker is constantly monitored. The work plan of the cutting room masterfully optimizes another intelligent module

– InvenTex Cut Plan.

Program Main Functions / Benefits for Users

• very easy to create new cutting markers through an intuitive marker wizard

• creation of new markers on the base of existing ones, swapping sizes in the marker while maintaining their position, joining few markers into one marker

• ability to work with multiple open markers at the same time

• simultaneous generation of markers for different groups of materials within one cutting order

• automatic templates fitting to the materials checks report, strips report or fabrics motives formulas

• automatic patterns scaling for selected shrinkage parameters, assigning the shrinkage values to the fabrics

• support of faults on the fabrics, defining of overlap lines for fabric spreading process

• ability to group and catalog the markers by many criteria, easy searching and filtering for the markers

• ability to edit the shape and key parameters of elements directly from MGS module

• fast copy and move of patterns between sections and other markers

• synchronizationofelementsrotationwithin eachbundle, synchronizationofrotationfor the elements within all bundles at one given size (all elements in the bundle will always rotate synchronously), or synchronization of rotation for the elements within all bundles for the all sizes together

• advanced creation of fusing groups with separated support of their shrinkage ratio. Possibility to move fusing group automatically from the marker for main fabric to the “fusing” marker consisting of elements to be fused

• adding to just ready marker of new size, new product/model or next elements even from the another model, not existing in the ready marker – ex. in purpose to make marker efficiency higher

• ability to cut selected elements in the marker in purpose to obtain higher marker efficiency (less fabric waste)

• smart update of existing ready-made markers in case of: change of pattern shape, change of notches, change of patterns quantity in a model, or making another changes in the patterns. Update is supported by list of changes.

• The largest work area on the screen, most information on one screen, work with full resolution Full-HD or higher (1920×1200,

2.3 million pixels)

• user-profiled interface (icons, tool bar, keyboard shortcuts, colors, etc.)

• profiled data import from the cooperating parties, recorded in all international formats

• generation and profiling of marker files to be used with professional plotters and automatic cutting machines

• and many others…

possibility of placing elements in selected areas of the marker, so-called “sections” (horizontal or vertical)